Three ways to judge the quality of powdered hydroponic nutrient products

Commercial hydroponic nutrients are often available as liquid concentrates. These offer a very reproducible experience for the user, with very high homogeneity and easiness of application. However, one big drawback of liquid concentrates is the fact that they contain a significantly large amount of water, meaning that shipping them is often very expensive. The solution to this is to create solid state fertilizers, where a mix of raw salts is shipped, and a concentrated stock solution or final hydroponic nutrient solution is prepared by the user. However, solid preparations have some important issues that liquid concentrates do not have that can significantly affect the quality of the nutrition received by the plants and the reproduciblity of their results. In this blog post, we will talk about what makes a good premixed solid fertilizer and thee ways in which you can judge the quality of one.

Homogeneity of the product. Having a very finely mixed fertilizer is extremely important because hydroponic fertilizers can contain nutrients with differences in composition of even more than 3 orders of magnitude. A fertilizer might contain 10% of its mass as nitrogen but only 0.01% of its mass as iron. For that fertilizer to work effectively, any random sample draw from it must contain as close as possible to the composition on the label. However, if the fertilizer is not well mixed a random draw might deviate very strongly from the intended composition. This means that one day you might be preparing a batch of solution using a 20%N 0.001%Fe fertilizer and the next day you might be preparing one that is 10% N and 0.5% Fe.

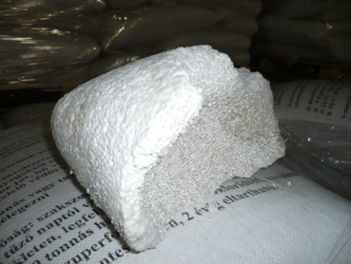

A good quality solid fertilizer product should have a homogeneous look to it. You should be unable to determine the constituent salts from one another in the fertilizer mix. If you notice different types of solids within the product – such as pellets mixed with crystals – or any other sign that the preparation is not homogeneous then this means that the fertilizer is just a very simple mix of the raw salts, meaning that the components may separate relatively easily as a function of time through differences in their properties (such as density). Sometimes a fertilizer might be finely ground, well mixed and then pelleted – which is acceptable – but if this is the case the fertilizers should contain only pellets and all of them should have the same look to them.

If you want to really tell if the fertilizer is of good quality you can take random samples from different parts of the fertilizer – punch different holes in a sealed bag and sample from different sections of it – and send them for lab analysis. The standard deviation of the composition of the different samples will tell you how good the fertilizer is. Good solid fertilizers will have a standard deviation below 5% in analyzed samples.

Stability of the product. A good solid fertilizer product will be stable through time, since it will be formulated with salts that are as close as possible to the lowest thermodynamic state of the mixture of ions being made. Inexperienced people who venture into the fabrication of solid fertilizers will often mix salts that are used in liquid concentrates that can react when put together in solid form. These reactions often happen with a release of water that can change the weight of the fertilizer as it evaporates from the product or can cause very significant caking problems in the mixture as a function of time. In the worst cases, some substances that are hard to put back into solution might form, making the final use of the fertilizer difficult.

You can tell if a fertilizer is reacting if there are changes in the mass of the fertilizer as a function of time or if the appearance or physical properties of the fertilizer change. Are the colors changing? Is the texture changing? All of these things can point to on-going reactions in the fertilizer mixture that can be indicative of problems with the formulation. A good formulation should change as little as possible through time.

Easiness of dissolution. Premixed solid fertilizers for hydroponics need to be prepared to be as easy as possible to dissolve in their final application. This can be problematic depending on the inputs used, but adequate additives need to be put in to ensure that the products will not have a very hard time getting back into solution. This involves adding adequate wetting agents as well as ensuring that chemical reactions that alter solubility do not happen within the final product.

When dissolving raw fertilizers most of the product should go into solution, however – depending on the purity and source of the chemicals used – some insoluble portions might remain. A manufacturer might make the choice of using inputs that are directly mined instead of chemically purified – using for example OMRI grade magnesium sulfate – this will create a product that has more insoluble materials compared to a product that uses more thoroughly refined magnesium sulfate. Whether this is acceptable or not will depend on the type of application required and what the priorities of the grower are, for example MRI compliance might be more important than having better solubility.

As you can see, although solid premixed fertilizers can provide significant savings in terms of shipping over liquid concentrated fertilizers, they can do so at the cost of reproducibility and quality problems.To avoid these problems I recommend you ensure the fertilizer you choose to use has been properly blended to produce low deviations in sampling, has been formulated with thermodynamic stability in mind and has been formulated considering proper solubility in the final application.