Five important things you should know about humidity in hydroponics

Humidity is one of the most important metrics in hydroponic culture. In order to have a successful crop it is critical to understand what humidity actually is, how we measure it, why we need to control it and where we want it to be. Today I want to share with you five things you should know about humidity in hydroponics. These pointers should be equally useful to newer growers and those who want to get even higher performance out of their current hydroponic crops.

There is a big difference between relative humidity and absolute humidity. Although we generally understand humidity as the amounts of water in the air in reality what we usually measure in hydroponics is “relative humidity” (RH) which does not measure how much water there is in the air but what percentage of the available capacity we are using. A measure of 70% tells you that the air currently holds 70% of the water it could hold, but it doesn’t tell you anything about how much water there actually is in the air. Absolute humidity, on the other hand, tells you how much water you actually have in the air. As warmer air can carry significantly more water it is important to realize that a 70% humidity at 80F implies there is way more water in the air than a 70% humidity measurement at 50F.

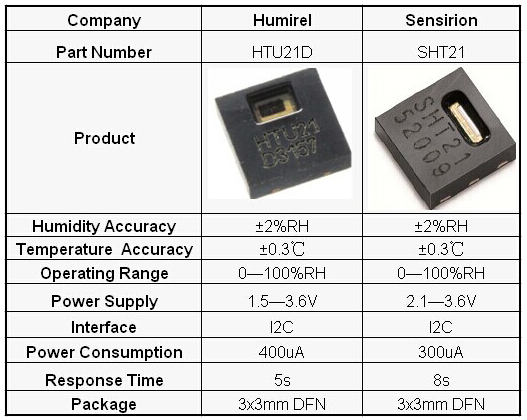

Relative humidity meters are not reliable instruments. We often buy instruments to monitor ambient conditions without much thought about how they work or how good or bad they are. Relative humidity is a tricky measurement and cheap, semiconductor based relative humidity meters have not been very reliable or accurate. Usually a humidity meter will have an error of +/- 5% and it’s accuracy will not be on point if it has been exposed to very high humidity values (if there was ever any condensation on the sensor it probably was damaged to a significant extent). I often recommend buying at least 3 instruments with different chipsets. Having just one – or even several meters with the exact same chip – can be a recipe for disaster. The chipsets below are setting a new standard for precision and accuracy, so I would recommend you give sensors with those a try if you’re looking for more accurate RH measurements.

It is often better to go over than to go under. Although higher or lower relative humidity values are both sub-optimal for plants, it is often better to go with higher humidities rather than lower humidities in terms of crop yields. Lower RH values will tend to stress plants more – especially if the temperature is high – while higher RH values are often easier to deal with for tropical plants (which are the kind we often grow in hydroponics). Although higher humidity can definitely cause important issues – such as fungal diseases – we have ways to deal with this that are more effective than our ways to deal with stress caused by low relative humidity. Of course extreme values will be very detrimental to plants either way, so when I say high consider I don’t mean 95% RH at 80F.

Relative humidity can change a lot depending where you measure it. It is important to place RH meters at different places that represent what the plant is actually being exposed to. If you place RH meters in a greenhouse, far away from plant canopy, you will get a very poor representation of what the plant is actually experiencing and you might try to increase humidity substantially when this might not be needed. Ventilation is critical to alleviate this issue but in order to stay on top of it I always advice having meters within plant canopies in order to know for a fact how much your humidity values diverge between different places in your growing environment. Humidity is always bound to be higher closer to plants – as they transpire – but we should know how different it is. A big difference is a strong hint that there is not enough ventilation around the plants.

Humidifiers are often needed during the winter. Most crops that grow in warehouses during winter times require humidifiers, since the plants often do not evaporate enough water to compensate for the complete lack of water within the dry winter air (this is specially true if the volume of the growing warehouse is large). If you want to have a successful crop during winter times it will be paramount for you to have adequate humidifiers to ensure that your RH values are within what’s ideal for your plants. Depending on the size of your crop this might require significant planning and investing so make sure you always consider this when designing your winter growing cycles.

I hope you have found the above pointers useful. There are certainly many other important aspects of humidity, such as relative humidity meter calibration, judging ideal humidity using vapor pressure charts, or ensuring that plants have enough defenses if they happen to get exposed to exceedingly high humidity levels within their canopy. We will certainly discuss some more of these within future posts!