I have written several posts in the past about the measurement of water content in media, I have covered some very low cost and easy to use sensors that can also be plugged into Arduinos using i2c as well as some of the more accurate sensors you can get for this in hydroponics. However, there are several companies that offer more plug-and-play solutions for the monitoring of moisture in media and the setup of automated irrigation schemes using these measurements. The company Vegetronix offers moisture sensors that are insensitive to salt in media that can be plugged straight into boards that contain relays that can be used to control irrigation pumps. In this post, we will talk about these sensors, how they operate and how you could use them to automate irrigation within your growing room or greenhouse without much coding or setup efforts required. This post is not sponsored by Vegetronix and I have no association with them.

The main offering of Vegetronix in terms of moisture monitoring is their VH400 sensor, this sensor has the advantage of being completely waterproof and rugged in construction. It can be placed deep inside media – right next to the root ball – which is a huge advantage in hydroponic setups that use cocoa or peat moss and use large amounts of media per plant. The small size of the sensor also means that this will be more practical for something like rockwool compared with a sensor like the chirp, which has exposed circuity and cannot be fully submerged. In addition, the VH400 is also suitable for outdoor use. Another thing I like about these sensors is that they are analogue and can therefore be interfaced quite simply with Arduinos or other such control mechanisms, making them great for DYI. This would make them a great candidate to interface with a cricket board, which I showed in a recent post.

The technology used in these sensors is however kept secret. Given that the sensor has no exposed ceramic or metal leads, it would be fair to assume that it is capacitive in nature and probably uses a technology similar to the Chirp sensor, although it is difficult to know precisely how it carries the measurements without doing some heavy reverse-engineering of the sensors. One of its key features though is that it is unaffected by salinity, which is a key requirement for accurate measurements in hydroponics, and – given the lack of exposed metal leads – we are sure this is not a resistive sensor. Vegetronix does not seem to hold any patents on the sensor – please correct me if I’m wrong – so it is fair to assume that the technology is probably well within the well-known techniques in the field.

It is worth noting however that – although advertised as “unaffected by salinity” – it will require routine maintenance, washing with distilled water to reduce salt accumulation and recalibration to ensure it is giving accurate moisture content measurements. As with all moisture sensors, adequate calibration and monitoring of sensors is fundamental to long term success with them. If these sensors are not maintained they will stop giving proper readings with time, especially if they are buried around the root zone of plants in hydroponic setups.

Another important point is that these are low cost sensors and have significant fabrication differences between them, proper and individual calibration of all sensors is required for proper quantitative use.

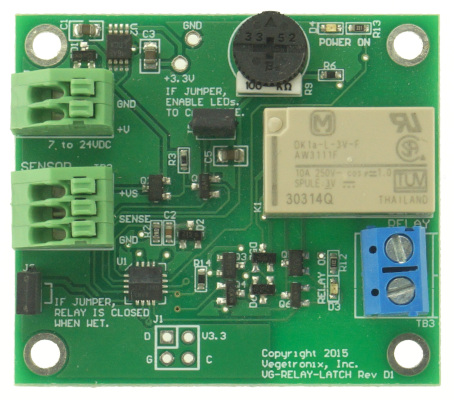

With the sensors in mind, we can now discuss the relay boards that make this choice quite attractive. The board shown above, which you can find here, is a battery-powered sensor that links to a single VH400 sensor to trigger a pump at a given moisture sensor threshold. All it takes to use this sensor is to perform a calibration procedure using the VH400 sensor and use the screw on the board to set the point where you want the relay to trigger. The board is 60 USD and the VH400 is 40 USD – at the shortest cable length – so with these two sensors you can set up a quite decent irrigation setup that is fully automated and battery-powered, with minimal wiring required.

However, if you want a more extensive setup, you can get their relay hub, which can connect to popular cloud data services in order to send your data to the cloud while also being battery-powered and allowing for triggering of an irrigation system using multiple sensor readings or input from the cloud. Although this relay box is more expensive, at near 150 USD when you consider the battery accessories, it does provide you with a lot of additional options if you want access to remote monitoring of your moisture sensors. Since it can relay the data to third-party sites like thingspeak, it would be relatively easy for an experienced programmer to hook all that data into a central database to put it together with data from other sensors.

So although the Vegetronix sensors are not my preferred solution if a fully DIY setup is possible – if enough time, experienced personnel, and financial resources are available – I do believe that they make a very good value offer for those who want a decently accurate setup to monitor soil moisture content without the hassle of having to deal with the complications of a fully DIY setup. Their boards offer both super simple, low-cost solutions and more elaborate solutions for those who give more importance to data logging and monitoring. If you aren’t controlling your irrigation with moisture sensors, a quick 100 USD setup of VH400+battery powered relay station is a huge step in the right direction.